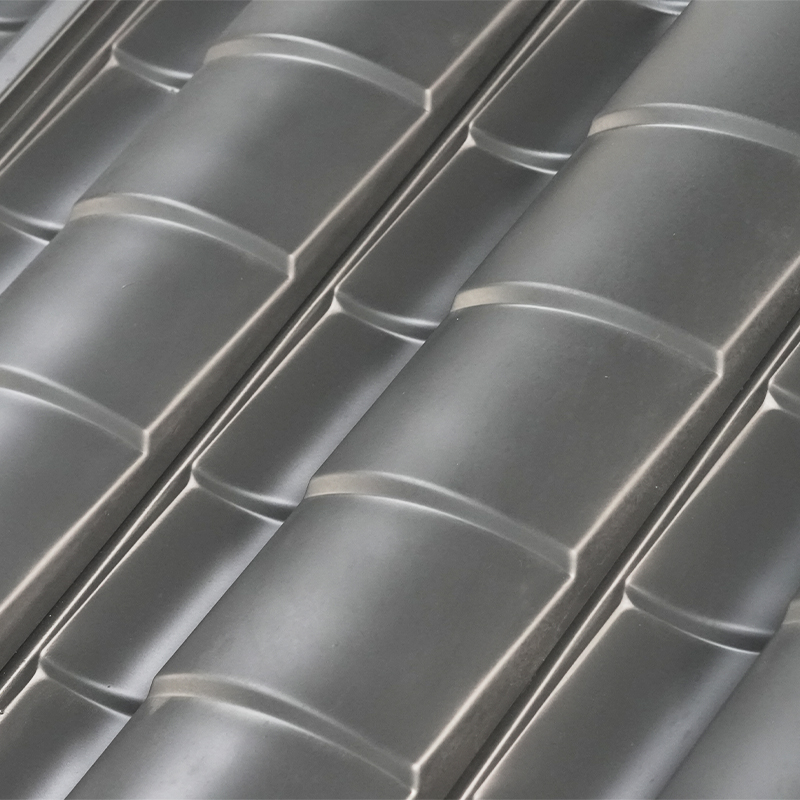

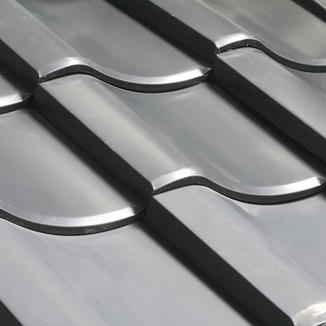

Minimizing imperfectionibus et inconvenientia in productionem Aluminium pompis sheeping Est critica ad concupiscentiam eorum uniformis euismod, diuturnitatem, et aesthetic appeal. Infra sunt key modi et processibus in vestibulum ad consequi hoc:

I. Material Electio

High-Quality Alloys : Manufacturers select aluminum alloys specifically designed for roofing applications, such as 3003, 5052, or 6061, which offer excellent corrosion resistance, formability, and strength.

Puritas control, cursus humilis campester of impudicitiis in rudis materiae adjuvat ponere consistent mechanica proprietatibus et reduces periculum defectus.

II. Precise volubilem processibus

Frigore Rolling: Aluminium pretium sunt advolvit ad precise crassitudines sub moderari conditionibus ad eliminate crassitiem varietates et ensure uniformitatem.

Tensio Control, applicando consistent tensio durante volubilem prohibet warping, grackling, aut inaequalis crassitudine distribution.

Annealing: calor curatio (annealing) adhibetur ad levare internum passiones et amplio sheet in formability et dimensional stabilitatem.

III. Superficiem curatio

Purgato et degreasing: laminas penitus purgari tollere olea, oxides, aut contaminantium quod posset afficit superficiem quale vel coating adhaesionem.

Chemical Treatments: processibus sicut Chromate vel PHOSPHATE conversionem coatings augendae corrosio resistentia et providere firmum basi pro pictura vel laminating.

Anodizing: ElectroChemical Anodizing creates dura Oxide iacuit, quod amplio duritia, gerunt resistentia, et color retention.

IV. Coating Technologies

Pulveris coatings: uniformis application of pulveris coatings ensures consistent color, textura et tutela proprietates per sheet.

Liquid Pigmenta: Advanced RAMULUS systems cum automated controls praestare etiam coverage et minimize Virges aut FORMA.

Qualis checks: iactaret laminas subeunte stridore temptationis ad Caesarem, tempestas resistentia, et glossa uniformitas.

V. Qualis imperium mensuras superiores

In-linea inspectionem: automated inspectionem systems deprehendere defectus ut scalpit, dents, aut crassitudo variationes per productio.

Ultrasonic Testing: solebat identify internum vitiisque, ut evacuat aut inclusions, quod potest compromissum fabrica integritas.

Dimensional accurate: laser mensurae Tools quin quod laminas occursum certa dimensiones et tolerances.

VI. Post-vestibulum processus

Tondentur et secare: praecisione cutting apparatu ensures mundus oras et accurate magnitudinum, reducendo likelihood burrers et deformationes.

Packaging, propriis packaging protegit laminas a dampnum per translationem et repono, prohibendo scalpit et corrosio.

VII. Environmental controls

Temperatus et humiditas ordinatione: maintaining firmum environmental conditionibus durante productio minimizes oxidatio et warping.

Fusce-Free ambitus, munda rooms vel regi atmosphaeras ne contagione de laminas in dispensando.

VIII. Testing et sanatio

Mechanica temptationis: Tensile, flectere, et impulsum probat cognoscere sheet est fortitudinem et ductility.

ROSIO resistentia Testing: Salis imbre aut accelerated tempestas probat assess diu-term diuturnitatem in variis climatibus.

Visual Inspectiones: Inspectiones Final per eruditos personas ut et laminas occursum aesthetic signa ante sit amet.

IX. COMMENDIUM

Feedback ansas: Manufacturers analyze Customer Feedback et agri perficientur data ad refine productio procedit et oratio recurring proventus.

Technological Profectus: Investing in Novus Machinery et ars, ut robotic automation et Ai-repulsi qualis imperium, enhances constantiam et efficientiam.